Your trusted provider of Gas Abatement Systems

408-887-6132

Emergency Release Scrubber Application Notes

Overview

To accurately understand the abatement issues for any given process, it is necessary to understand the process in the tool, the chemicals that are put in, and how the process modifies them. The following overview represents our understanding of this process and is the basis of this recommendation.

Semiconductor processing involves a great many hazards. Storing large quantities of any high pressure gas represents a significant danger. In addition to the dangers associated with high pressure gases, the nature of the gas can also cause problems. The hydride series of gases are some of the most toxic gases currently used in any industry. Arsine (AsH3) and phosphine (PH3), two of the most common hydrides used in semiconductor processing, are more deadly than hydrogen cyanide, which is used in the gas chamber.

Especially challenging is what to do in the event of a leak in a gas cylinder cabinet. If this leak were to continue unabated, an extremely deadly cloud could endanger those in the fab, or it could emerge from the plant, causing great harm to the area surrounding the fab. These leaks typically arise when some component of the cylinder fails, and gas escapes from the cylinder into the surrounding area.

For this reason, gas cylinders are typically stored in gas cabinets, which are ventilated enclosures. This ventilation is designed to pull leaking vapors out of the cabinet, and away from nearby personnel inside the fab. However, the ventilation must still be treated in the event of a toxic gas leak. It is not safe to allow these gases to escape into the atmosphere, where they could endanger those around the fab.

Typical Recipe

A typical release occurs from a high pressure cylinder into a gas cabinet. The typical ventilation from a gas cabinet is 200 – 300 cubic feet per minute (cfm). In many instances the exhaust from several gas cabinets is joined together into a common header. The flow through this header will determine the final volume of air which must be treated.

Consideration for an emergency release situation accounts for one cylinder failing at a time. The release rate from the cylinder will depend on several factors. The pressure of the cylinder, and the size of the hole are the two main factors. A hydride gas cylinder should be equipped with a restrictive flow orifice (RFO). This small opening will limit the rate at which gas can escape a cylinder. This is an important safety feature, because it creates “less dangerous” emergency situations, by reducing the release rate, and keeping the concentration of the released gas lower.

Abatement Considerations

It is important to have abatement in place for an emergency release because of the extremely toxic nature of the hydride gases. TLV is the Threshold Limit Value for a gas. This is the maximum time weighted average exposure for an 8 hour period. IDLH is the level that is an Immediate Danger to Life and Health. This is the concentration that represents a danger after 15 minutes of exposure. This table shows the gases of the hydride family which are typically protected with an emergency release scrubber in a semiconductor fab.

Any abatement solution must be properly sized to handle a full cylinder release of any gas. Therefore, if a dry system is used, it must be of sufficient size to abate the larger gas cylinders which are being used today. The unit must also be capable of handling the total flow which will pass through it. Because several gas cabinets are often sent to the same scrubber, the total flow is often too high for a thermal type unit. Thermal units can also create byproducts which are also toxic, especially if arsine is burned.

The ideal emergency release scrubber is also passive. An emergency release is not an event which people expect to happen, so they should not have to spend long periods of time worrying about the abatement solution they have chosen. Water scrubbing technology, with its need for chemical injection for hydride destruction, can be a very time consuming and messy solution for this application. In addition, water scrubbers often do not have the required efficiency to reduce an emergency release to safe levels.

BAZM Solution: ERS

When considering emergency release of hydride gases, BAZM recommends a dry scrubbing solution. The ERS module is ideal for hydride release abatement. Once all the relevant information about cylinder size and pressure, amount of gas to be scrubbed, RFO size, and total flow to the scrubber is known, we can properly size an ERS unit for your needs.

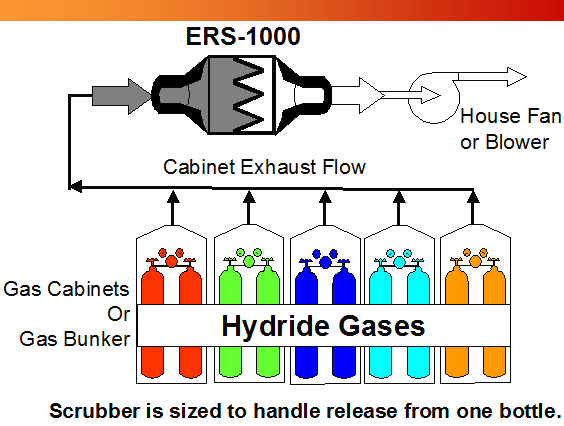

An ERS unit from BAZM is designed to be installed directly inside the exhaust duct. The ventilation flow from several gas cabinets can be connected to a single ERS scrubber. As the total flow increases, or the amount of gas to be scrubbed increases, the size of the ERS scrubber will also increase. The ERS unit can be comprised of up to 9 ERS 1000 units. The ERS1000 is the basic unit, which is combined with other units in parallel if necessary.

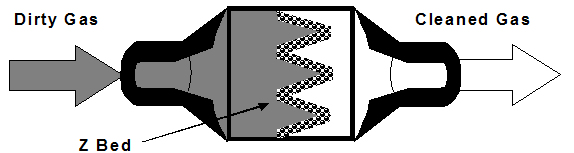

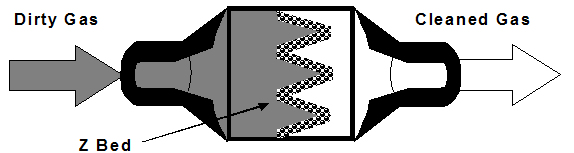

The ERS uses a Zbed configuration, as shown above. This Zbed allows the scrubbing media to be contained in a much smaller volume than otherwise possible. The gas cabinet exhaust flows through the Zbed design of the scrubber, and any hydrides which are present get scrubbed by the resin media.

ERS units arrive filled with resin designated R50. The capacity of this resin depends on the type of gas being flowed, the inlet concentration, and the flow rate. We use a wide range of capacity data to properly size the emergency release scrubber.

One of the most frequently asked questions about the ERS systems is the lifetime of the resin. Due to the “install and forget” nature of the ERS, it is quite often not checked or evaluated again after installation. However, it could be years until the unit is needed to abate a hydride release. BAZM takes possible degradation into account when sizing an ERS unit for a customer.

In the event of an emergency hydride release, the system will need to be replaced. This is due to the consumption of the resin. If a release were to take place through a spent system, there would be little or no scrubbing, and the release would escape to the atmosphere and could cause harm. A resin change is easily performed by a "bagin, bagout" technique, which minimizes worker exposure to the spent resin material.

Example ERS1000 Facilities Requirements*

*Facilities requirements will change with larger modules. Please consult your representative for more information.

Abatement Chemistry

The ERS uses a proprietary resin mixture to convert hazardous hydride gases to their corresponding oxides. Because the reaction creates solids, and takes place inside the pores of the resin material, the oxide products are trapped, and can easily be disposed of.

Efficiency

The ERS unit is designed to abate hydride gas releases to below ½ IDLH levels. Under most emergency release conditions this equates to an efficiency >99%.

Typical Process Flow Diagram

This diagram represents a "typical" process. Actual processes may differ from the process shown here.

To accurately understand the abatement issues for any given process, it is necessary to understand the process in the tool, the chemicals that are put in, and how the process modifies them. The following overview represents our understanding of this process and is the basis of this recommendation.

Semiconductor processing involves a great many hazards. Storing large quantities of any high pressure gas represents a significant danger. In addition to the dangers associated with high pressure gases, the nature of the gas can also cause problems. The hydride series of gases are some of the most toxic gases currently used in any industry. Arsine (AsH3) and phosphine (PH3), two of the most common hydrides used in semiconductor processing, are more deadly than hydrogen cyanide, which is used in the gas chamber.

Especially challenging is what to do in the event of a leak in a gas cylinder cabinet. If this leak were to continue unabated, an extremely deadly cloud could endanger those in the fab, or it could emerge from the plant, causing great harm to the area surrounding the fab. These leaks typically arise when some component of the cylinder fails, and gas escapes from the cylinder into the surrounding area.

For this reason, gas cylinders are typically stored in gas cabinets, which are ventilated enclosures. This ventilation is designed to pull leaking vapors out of the cabinet, and away from nearby personnel inside the fab. However, the ventilation must still be treated in the event of a toxic gas leak. It is not safe to allow these gases to escape into the atmosphere, where they could endanger those around the fab.

Typical Recipe

A typical release occurs from a high pressure cylinder into a gas cabinet. The typical ventilation from a gas cabinet is 200 – 300 cubic feet per minute (cfm). In many instances the exhaust from several gas cabinets is joined together into a common header. The flow through this header will determine the final volume of air which must be treated.

Consideration for an emergency release situation accounts for one cylinder failing at a time. The release rate from the cylinder will depend on several factors. The pressure of the cylinder, and the size of the hole are the two main factors. A hydride gas cylinder should be equipped with a restrictive flow orifice (RFO). This small opening will limit the rate at which gas can escape a cylinder. This is an important safety feature, because it creates “less dangerous” emergency situations, by reducing the release rate, and keeping the concentration of the released gas lower.

Abatement Considerations

It is important to have abatement in place for an emergency release because of the extremely toxic nature of the hydride gases. TLV is the Threshold Limit Value for a gas. This is the maximum time weighted average exposure for an 8 hour period. IDLH is the level that is an Immediate Danger to Life and Health. This is the concentration that represents a danger after 15 minutes of exposure. This table shows the gases of the hydride family which are typically protected with an emergency release scrubber in a semiconductor fab.

| Gas | TLV | IDLH |

|---|---|---|

| AsH3 | 0.05 ppm | 3 ppm |

| PH3 | 0.3 ppm | 50 ppm |

Any abatement solution must be properly sized to handle a full cylinder release of any gas. Therefore, if a dry system is used, it must be of sufficient size to abate the larger gas cylinders which are being used today. The unit must also be capable of handling the total flow which will pass through it. Because several gas cabinets are often sent to the same scrubber, the total flow is often too high for a thermal type unit. Thermal units can also create byproducts which are also toxic, especially if arsine is burned.

The ideal emergency release scrubber is also passive. An emergency release is not an event which people expect to happen, so they should not have to spend long periods of time worrying about the abatement solution they have chosen. Water scrubbing technology, with its need for chemical injection for hydride destruction, can be a very time consuming and messy solution for this application. In addition, water scrubbers often do not have the required efficiency to reduce an emergency release to safe levels.

BAZM Solution: ERS

When considering emergency release of hydride gases, BAZM recommends a dry scrubbing solution. The ERS module is ideal for hydride release abatement. Once all the relevant information about cylinder size and pressure, amount of gas to be scrubbed, RFO size, and total flow to the scrubber is known, we can properly size an ERS unit for your needs.

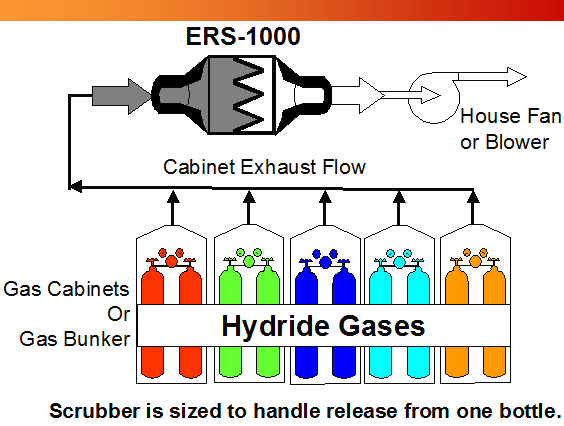

An ERS unit from BAZM is designed to be installed directly inside the exhaust duct. The ventilation flow from several gas cabinets can be connected to a single ERS scrubber. As the total flow increases, or the amount of gas to be scrubbed increases, the size of the ERS scrubber will also increase. The ERS unit can be comprised of up to 9 ERS 1000 units. The ERS1000 is the basic unit, which is combined with other units in parallel if necessary.

The ERS uses a Zbed configuration, as shown above. This Zbed allows the scrubbing media to be contained in a much smaller volume than otherwise possible. The gas cabinet exhaust flows through the Zbed design of the scrubber, and any hydrides which are present get scrubbed by the resin media.

ERS units arrive filled with resin designated R50. The capacity of this resin depends on the type of gas being flowed, the inlet concentration, and the flow rate. We use a wide range of capacity data to properly size the emergency release scrubber.

One of the most frequently asked questions about the ERS systems is the lifetime of the resin. Due to the “install and forget” nature of the ERS, it is quite often not checked or evaluated again after installation. However, it could be years until the unit is needed to abate a hydride release. BAZM takes possible degradation into account when sizing an ERS unit for a customer.

In the event of an emergency hydride release, the system will need to be replaced. This is due to the consumption of the resin. If a release were to take place through a spent system, there would be little or no scrubbing, and the release would escape to the atmosphere and could cause harm. A resin change is easily performed by a "bagin, bagout" technique, which minimizes worker exposure to the spent resin material.

Example ERS1000 Facilities Requirements*

| Inlet Connection | 10" flange | |

| Outlet Connection | 10" flange | |

| Weight | 1050 lbs | 476 kg |

| Footprint (H x W x D) | 38.0" x 55.0” x 31.0" | 965 x 1397 x 787mm |

*Facilities requirements will change with larger modules. Please consult your representative for more information.

Abatement Chemistry

The ERS uses a proprietary resin mixture to convert hazardous hydride gases to their corresponding oxides. Because the reaction creates solids, and takes place inside the pores of the resin material, the oxide products are trapped, and can easily be disposed of.

Efficiency

The ERS unit is designed to abate hydride gas releases to below ½ IDLH levels. Under most emergency release conditions this equates to an efficiency >99%.

Typical Process Flow Diagram

This diagram represents a "typical" process. Actual processes may differ from the process shown here.

©Copyright BAZM Solutions